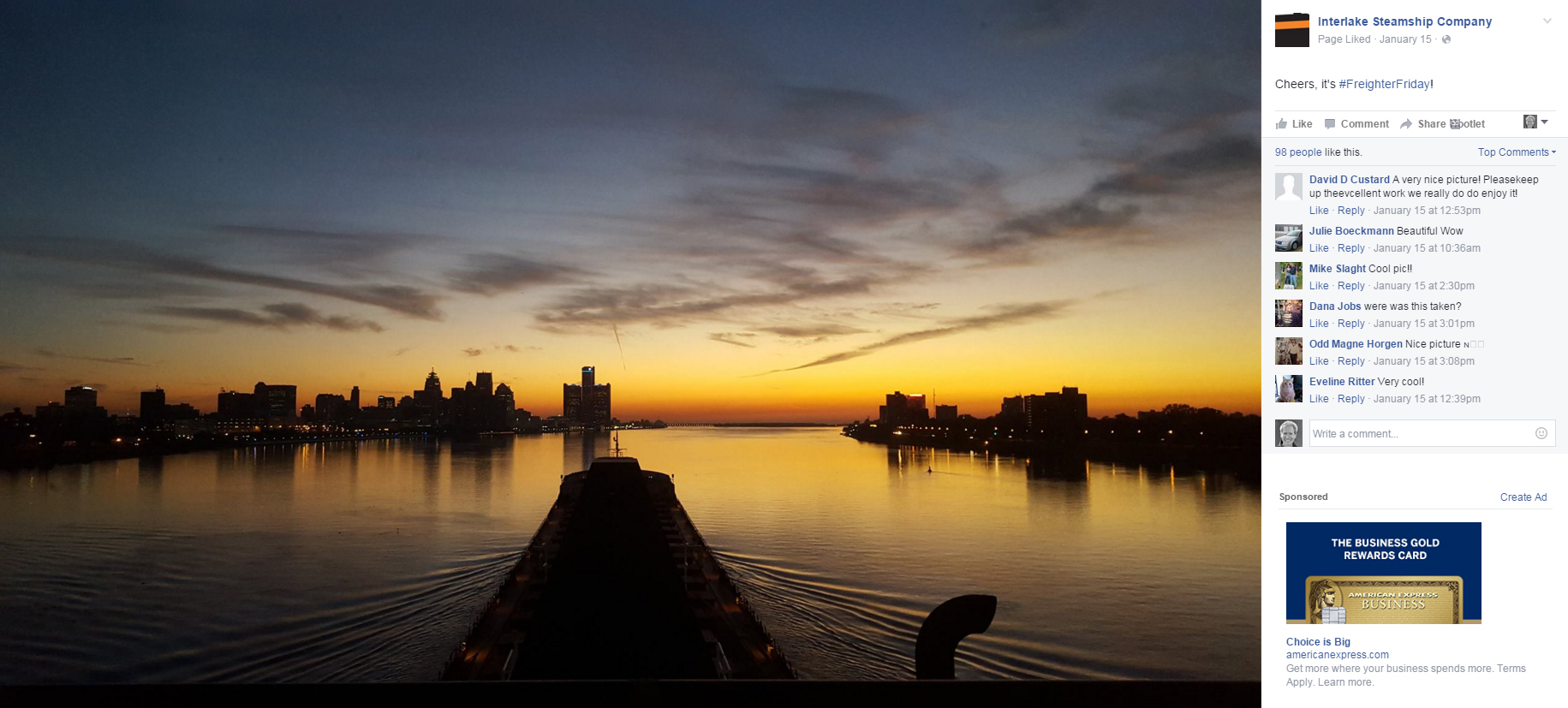

"It goes to show the power of social media and I'm pleased the video has touched a lot of people" said Mock. When asked why so many people have an affinity for Great Lakes ships like his, Mock replies "a lot of our audience are people who had family members work on the ships, and when they see this enormous vessel passing a beach or a port, it reminds them of their history."

Interlake Steamship Company's President, Mark Barker, has embraced social media as a way to inform the public on the merits of the maritime shipping industry. "It's great that people get to see what our talented employees do while learning about the positive impact our industry has on the local, regional and national economy"

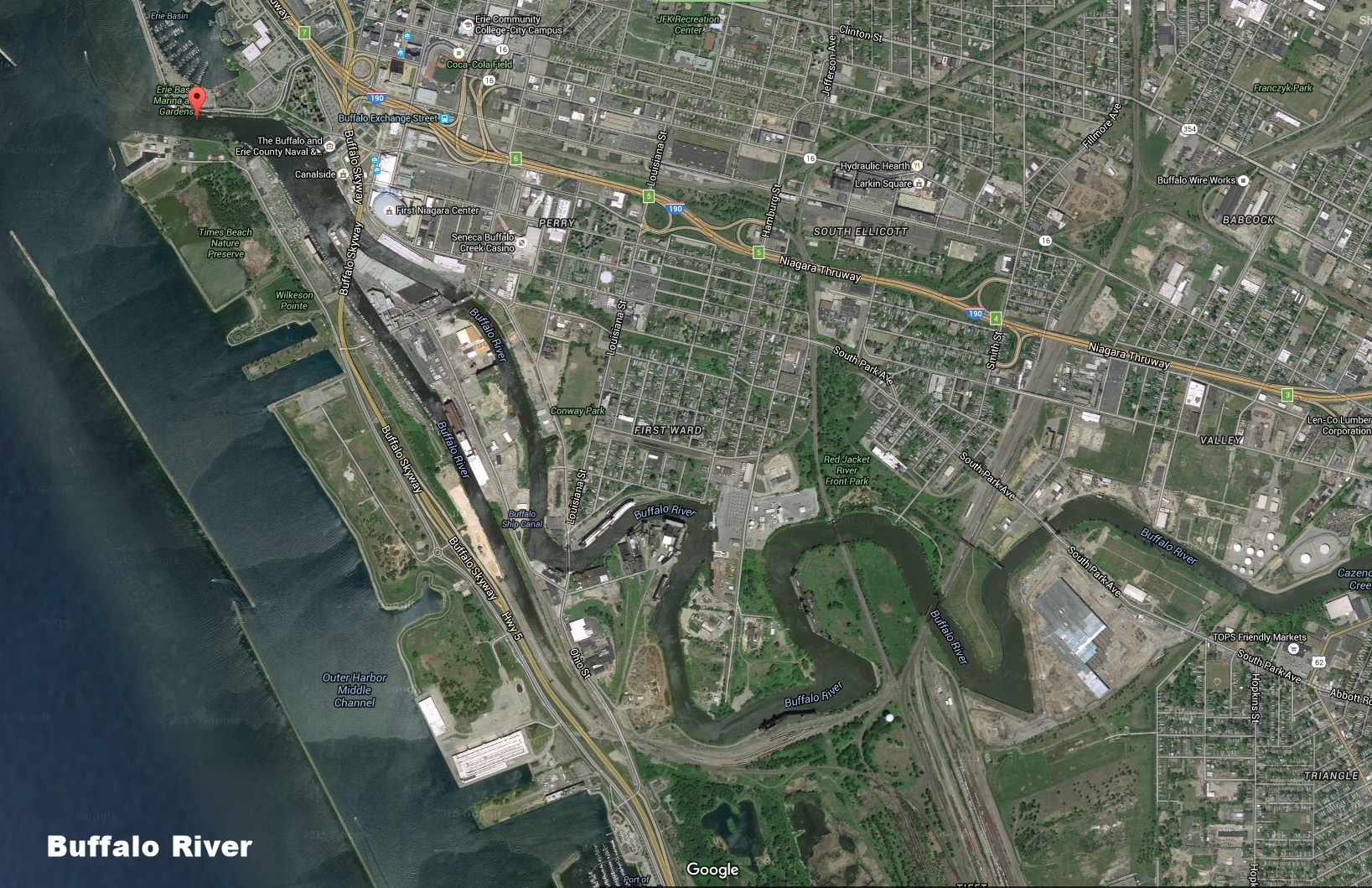

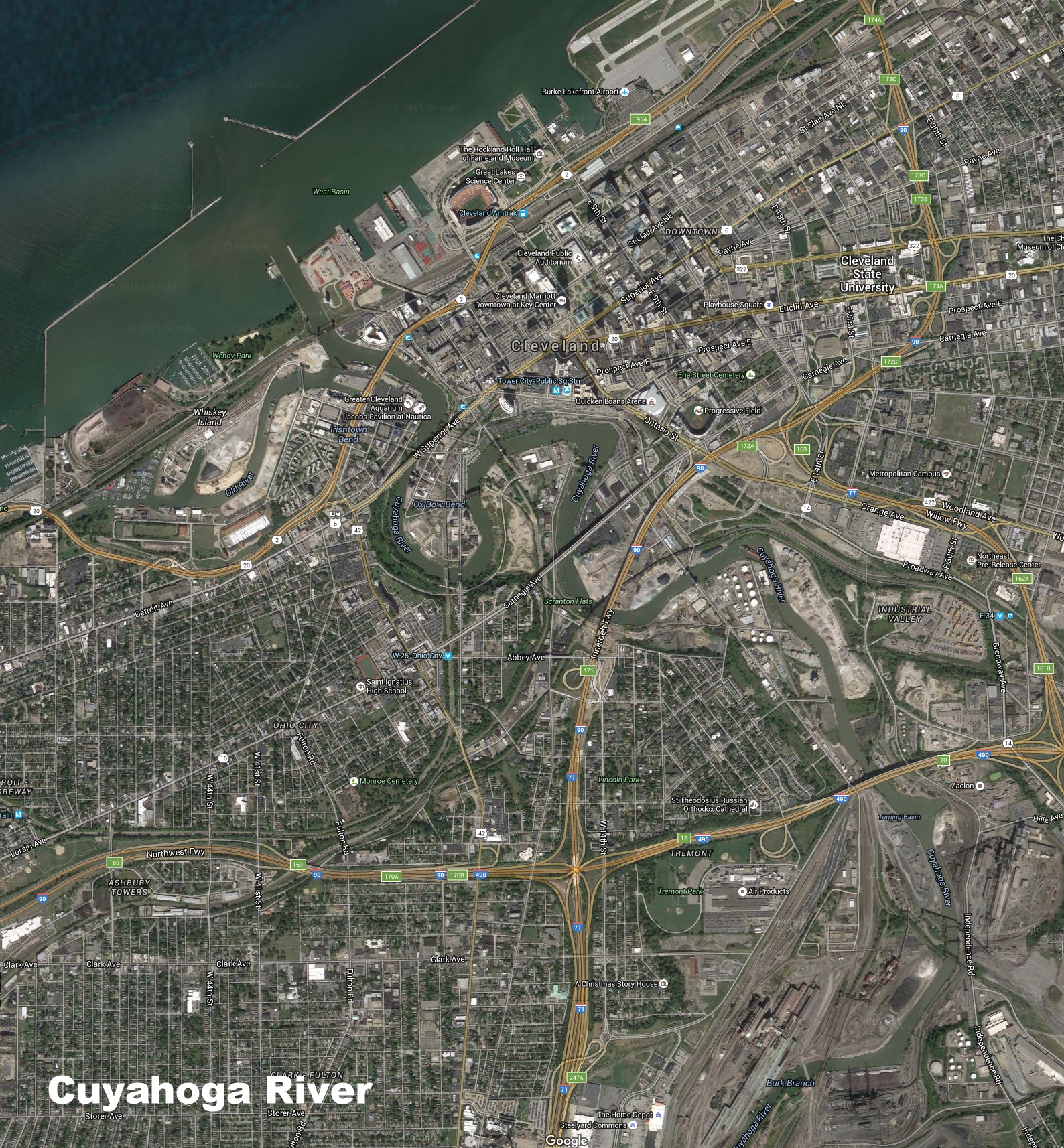

"We're a silent operation so folks don't know that much about us. People see trucks and rail cars all the time but ships aren't as visible - we come into a port, unload, and leave. In the Great Lakes our industry transports 100 million tons of raw materials per year in a safe, efficient and environmentally friendly manner. That's a great story that needs to get out there".